How to Choose the Right Industrial Work Benches for Maximum Productivity and Safety

In today's fast-paced industrial environments, the selection of the appropriate industrial work benches plays a crucial role in optimizing productivity and ensuring worker safety. According to a report by the Bureau of Labor Statistics, inadequate workstation design leads to approximately 30% of workplace injuries, highlighting the importance of ergonomically sound designs. Furthermore, a study by the National Safety Council indicates that well-organized workspaces can improve efficiency by up to 25%.

When choosing industrial work benches, factors such as material composition, height adjustability, and integrated storage solutions must be critically evaluated. By making informed decisions regarding these workspaces, businesses can not only enhance operational efficiency but also create a safer working environment that fosters employee well-being.

Understanding Your Workspace Requirements for Industrial Work Benches

When selecting industrial work benches, understanding your specific workspace requirements is crucial for maximizing both productivity and safety. According to the Occupational Safety and Health Administration (OSHA), proper workstation design can significantly reduce the risk of workplace injuries. In industries where heavy equipment is often handled, benches should be designed with safety features, such as rounded edges and non-slip surfaces, to mitigate hazards. OSHA's revised safety standards emphasize the importance of ergonomics in workbench selection, ensuring that benches allow for comfortable postures and easy access to tools.

Additionally, as reported in the AFL-CIO’s “Death on the Job” report, a safe workplace is essential not just for compliance, but for the overall well-being of employees. Statistics indicate that workplaces with organized, efficient setups see up to a 25% improvement in productivity. This is particularly true in environments where employees engage in repetitive tasks, making the choice of an appropriate workbench even more vital. A well-designed workbench not only enhances organizational efficiency but also plays a significant role in maintaining a safe working environment, reducing the likelihood of accidents and injuries related to workplace activities.

Identifying Key Features for Ergonomics and Safety in Work Benches

When selecting industrial work benches, prioritizing ergonomics and safety is crucial for enhancing productivity. Ergonomically designed benches should accommodate a variety of working heights, allowing users to maintain a neutral posture. Features such as adjustable height settings and tilt capabilities can significantly reduce strain on the neck, back, and wrists, promoting comfort during long hours of operation. Additionally, the surface material of the work bench should provide adequate support for tools and materials while minimizing the risk of slips or spills.

Safety features are equally important in the choice of work benches. Those designed with rounded edges can help prevent injuries from bumps or falls, while non-slip surfaces and adequate weight capacity ensure stability during usage. It is also beneficial to choose benches with built-in storage solutions, keeping tools organized and within easy reach to avoid accidents caused by clutter. Thus, by focusing on these ergonomic and safety aspects, companies can create a more efficient and secure working environment for their employees.

How to Choose the Right Industrial Work Benches for Maximum Productivity and Safety - Identifying Key Features for Ergonomics and Safety in Work Benches

| Feature | Description | Importance | Suggestions |

|---|---|---|---|

| Height Adjustment | Allows users to modify the height of the bench for ergonomic use. | High | Choose benches with manual or electric height adjustment features. |

| Material Durability | Constructed from robust materials to withstand heavy loads and wear. | High | Consider steel or thick laminate surfaces for heavy-duty use. |

| Storage Options | Includes drawers or shelving for tool and equipment storage. | Medium | Incorporate storage solutions that minimize clutter and improve organization. |

| Surface Finish | The top surface should be treated to resist spills and stains. | High | Select surfaces with a chemical-resistant finish for workshop settings. |

| Safety Features | Includes features such as rounded edges, non-slip surfaces. | Critical | Look for benches designed with built-in safety features to reduce accidents. |

Selecting Materials: Durability and Maintenance Considerations

When selecting materials for industrial work benches, durability and maintenance are crucial factors that directly impact productivity and safety. According to a report by the Industrial Designers Society of America (IDSA), work surfaces that are resistant to scratches, chemicals, and stains can significantly reduce downtime and maintenance costs. For instance, high-density polyethylene (HDPE) and stainless steel are often recommended for their superior durability—stainless steel, for example, can withstand heavy impact and is easy to disinfect, making it ideal for environments requiring stringent hygiene standards.

Additionally, the choice of material affects not just lifespan but also long-term costs. The National Institute for Occupational Safety and Health (NIOSH) states that choosing lower-maintenance materials can lead to operational efficiency. For example, a workbench made from particle board may be less expensive upfront but can deteriorate quickly in harsh environments, leading to increased replacement frequency. Investing in materials like powder-coated steel or hardwood laminates, though higher in initial cost, can provide a better return on investment by minimizing the need for repairs and replacements, ultimately enhancing overall safety and productivity in the workplace.

Choosing the Right Industrial Work Benches: Material Durability and Maintenance

This chart illustrates the durability and maintenance requirements of different materials commonly used for industrial work benches. The data highlights the importance of selecting appropriate materials to enhance productivity and safety in the workplace.

Assessing Bench Size and Configuration for Optimal Workflow

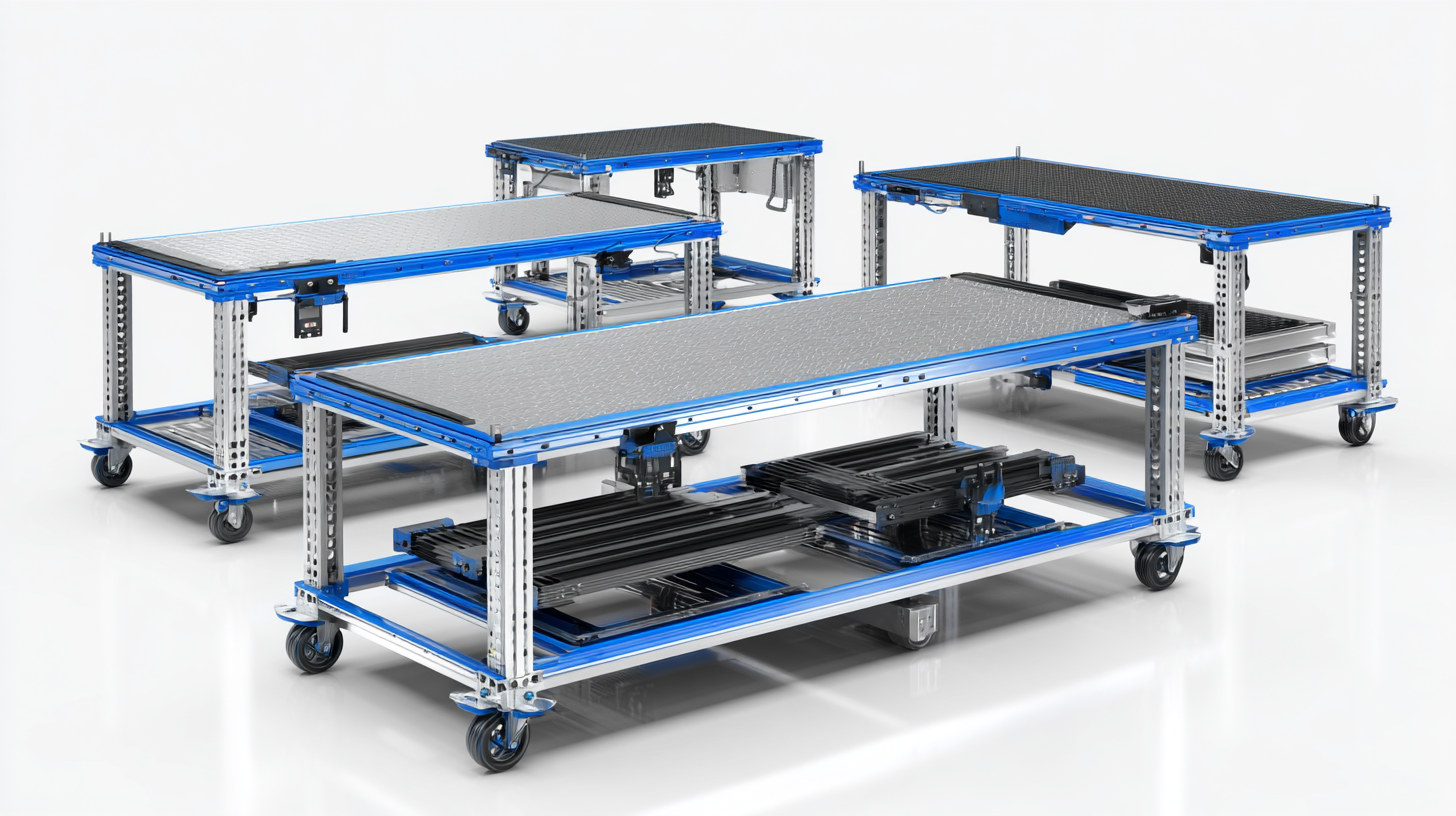

When choosing industrial work benches, assessing bench size and configuration is crucial for ensuring optimal workflow. A well-designed workbench not only accommodates the necessary tools and materials but also promotes safety and efficiency in the workplace. It is essential to consider the available space and the specific tasks to be performed. For instance, a larger bench may be required for projects that involve assembling large components, while smaller, adjustable models may better suit tasks requiring intricate detail.

Tips: Ensure the workbench height is adjustable to cater to different tasks and user preferences. This flexibility can significantly enhance comfort and reduce fatigue. Additionally, consider incorporating modular systems that allow for easy reconfiguration based on project needs, promoting an adaptable work environment.

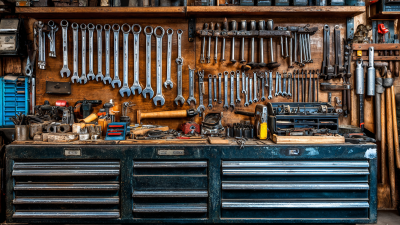

The layout of the workspace around the bench is equally important. An organized setup minimizes unnecessary movements and disruptions, facilitating a smoother workflow. Tools and materials should be positioned within arm's reach, reducing strain and enhancing productivity. Implementing a clear system for organizing supplies on or near the bench can further streamline operations, allowing workers to focus on their tasks with minimal distractions.

Integrating Storage Solutions to Enhance Efficiency and Organization

When selecting industrial work benches, integrating effective storage solutions is paramount for enhancing efficiency and organization in the workspace. The right storage components, such as shelving units, cabinets, and toolboxes, can optimize the use of available space, allowing workers to access essential tools and materials quickly. By implementing vertical storage systems, businesses can maximize floor space and maintain a clutter-free environment, which not only encourages productivity but also reduces the risk of accidents.

Moreover, customizing the storage options on work benches tailored to specific tasks can significantly improve workflow. For instance, incorporating modular storage solutions allows for easy reconfiguration based on project requirements, ensuring that everything from small parts to larger equipment is stored efficiently. Additionally, labeling and organizing items within reach can save valuable time during operations, further boosting overall productivity. By prioritizing organization through thoughtful storage integration, industries can create a safer and more efficient working environment.

Related Posts

-

Global Reach of China’s Elite Cabinet Workbench: A Synthesis of Quality and Innovation

-

How to Choose the Best Industrial Work Bench for Your Workspace

-

Unleashing the Power of Chinese Manufacturing for the Best Metal Work Benches Worldwide

-

How to Choose the Ideal Tool Chest Workbench for Your Workshop Efficiency

-

7 Best Work Table Designs to Transform Your Workspace

-

Exploring the Best Tool Storage Solutions: Features, Applications, and How to Choose the Right One

Footer

Resource Center

Contact Us

1901 West Main Street

Washington, MO 63090

Main Directory: 1-800-227-4873

Email: sale@pangcofurniture.com

Affiliations